In 1935 American composites manufacturer Owens Corning was formed, and during World War 2 it came up with a material that would go on to revolutionise a whole array of industries, not least of all car manufacturing. Glass-reinforced plastic (GRP), or glassfibre, was light, didn't rust, could be moulded to just about any shape, and could be easily repaired in the event of an impact.

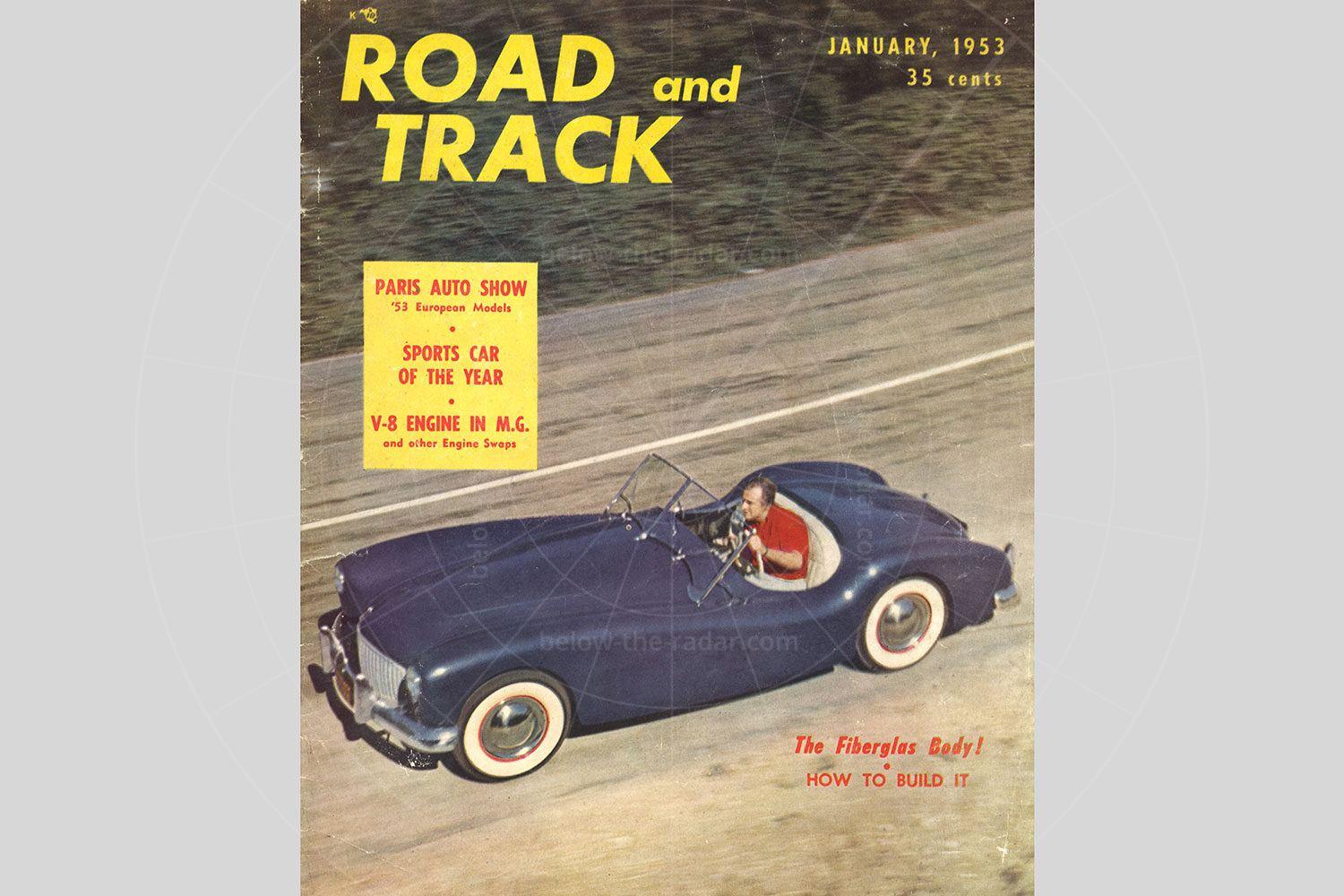

Throughout the 1950s and 1960s, the specialist car industry would mushroom on both sides of the Atlantic thanks to the adoption of glassfibre bodywork (NB: glassfibre is the generic term, while Fibreglass is a brand name). This lightweight wonder material could be moulded to any shape required, so it was much more versatile than aluminium or steel, and it was also far cheaper to work with.

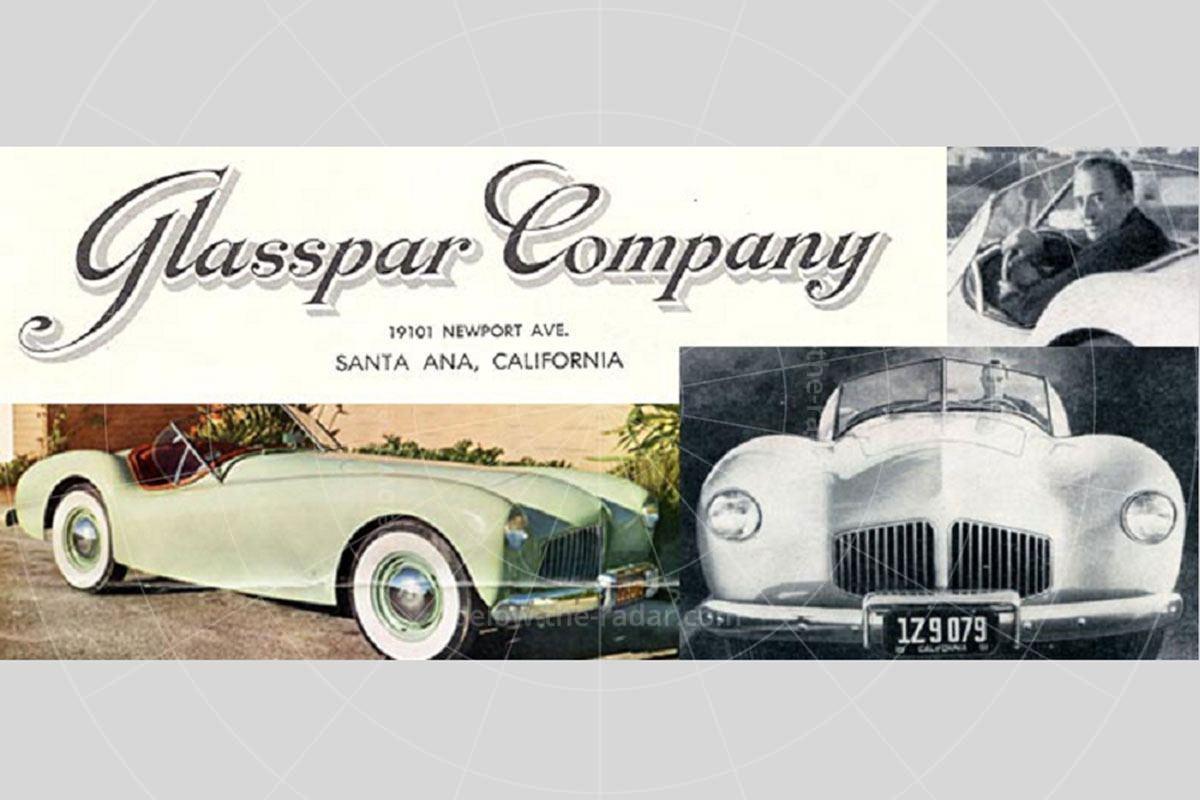

The man who started it all was Bill Tritt, who was born in 1917, then 30 years later in 1947, he started to build lightweight glassfibre-hulled boats, having started his career working for Douglas Aircraft. Tritt had founded his boat building company The Green Dolphin Boat Works with a business partner; a year later another friend John Green commissioned a racing sailboat to be built for him, called the Green Dolphin. Ultimately four of these boats would be made, giving Tritt's company some financial security, allowing them to expand their portfolio and for Tritt to set up a new company called Glasspar, to build glassfibre car bodyshells as well as to offer a wider range of boats.

A year later, in 1949, Newport Beach-based Air Force Major Ken Brooks was in the process of building his own hot rod, like many others at the time. Brooks based his car on a modified Willys Jeep frame with a significantly uprated Willys six-cylinder engine. He was trying to figure out what sort of body to put on the car, when he showed it to his friend Bill Tritt, who had a brilliant idea that would turn Brooks’ car into a sensation.

Brooks was toying with the idea of producing a steel or aluminium body for his car, as many other hot rod builders were doing right across America. After all, what alternative was there? But once Brooks started to talk to Tritt, everything changed, as Tritt convinced Brooks to build his car's bodyshell from glassfibre. Tritt came up with a few designs that featured both American and European influences; without the restrictions of working with metal, beautiful compound curves could be easily formed in the new material.

Ken Brooks and his wife Dolly were shown Tritt's sketches and they loved what they saw, instantly giving the as yet un-named car their approval, allowing work to start on building it early in 1950. Tritt set up wooden stations on the Jeep's chassis before producing a body plug, but disaster struck when one of Tritt's employees sprayed the Jeep's chassis with release coat, which meant the mould was stuck fast. Weeks and weeks of chiselling then followed, with precious time wasted in getting the car finished.

What was intended to be a three-month build turned into an 18-month project, with the glassfibre-bodied hot-rod finally finished in mid-1951 – just in time to be unveiled as the Brooks Boxer at the 1951 Los Angeles Petersen Motorama, where it was an instant hit.

By this point the Korean War was in full swing and the fledgling plastic boat building industry was starved of polyester resin, as it was all being retained for military use. But Tritt had a stroke of luck when he found out that the Naugatuck Chemical Company was opening up a new facility in Los Angeles.

Tritt drove to Los Angeles and introduced himself to Naugatuck's Bob Crawford who was very sympathetic, but he confirmed that he was unable to help because of the military-use only dictat. However, when Tritt climbed into the Boxer to drive away, Crawford was mesmerised by the car and he immediately contacted his Connecticut-based sales manager Earl Ebers to tell him about it. Ebers promised Tritt a month's worth of resin, lots of national publicity and an ample line of credit to get the project off the ground.

Tritt couldn't believe his luck, but what he didn't know was that Ebers had been trying to find someone who could build a glassfibre-bodied car as he was certain that this lightweight material that didn't rust was ideal for automotive bodyshells. Naugatuck commissioned Tritt to build a glassfibre car for display at the International Plastics Exposition in Philadelphia, in March 1952. Called Alembic 1, the two-seater roadster caused a sensation, and one of those who saw it was General Motors' chief stylist Harley Earl. He borrowed the Alembic 1 and just 10 months later Chevrolet introduced the Corvette, complete with a glassfibre bodyshell…

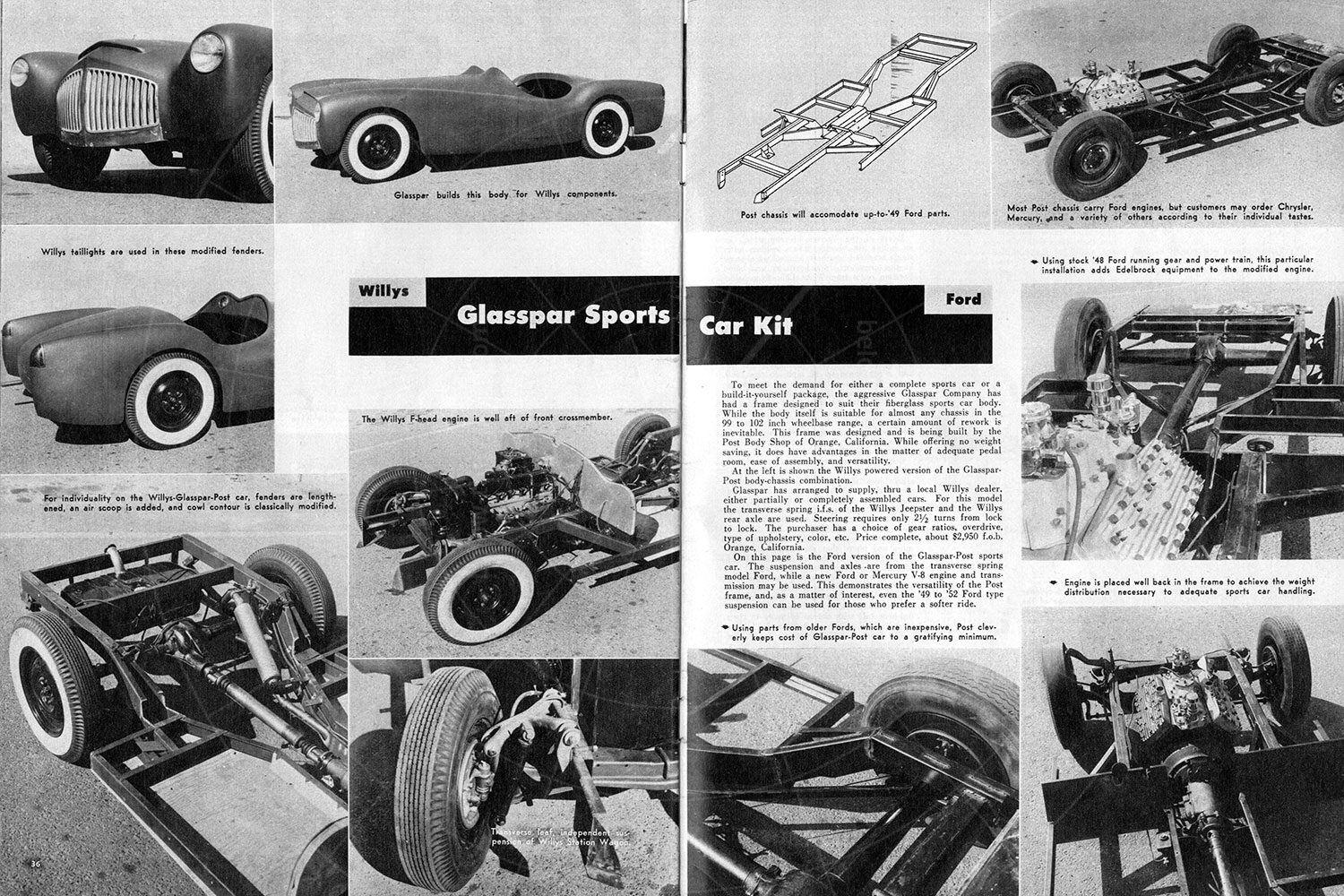

The Alembic 1 created such a stir that Tritt received far more publicity than he could ever have imagined, with features in Life Magazine, the New York Times, the Wall Street Journal along with many more high-profile publications. The response to this publicity was tremendous and it was clear that there was an opportunity here for him to put the car into production himself. So he did, as the Glasspar G2, which was available as a basic body kit or with a tubular frame to accommodate 1939-48 Ford running gear.

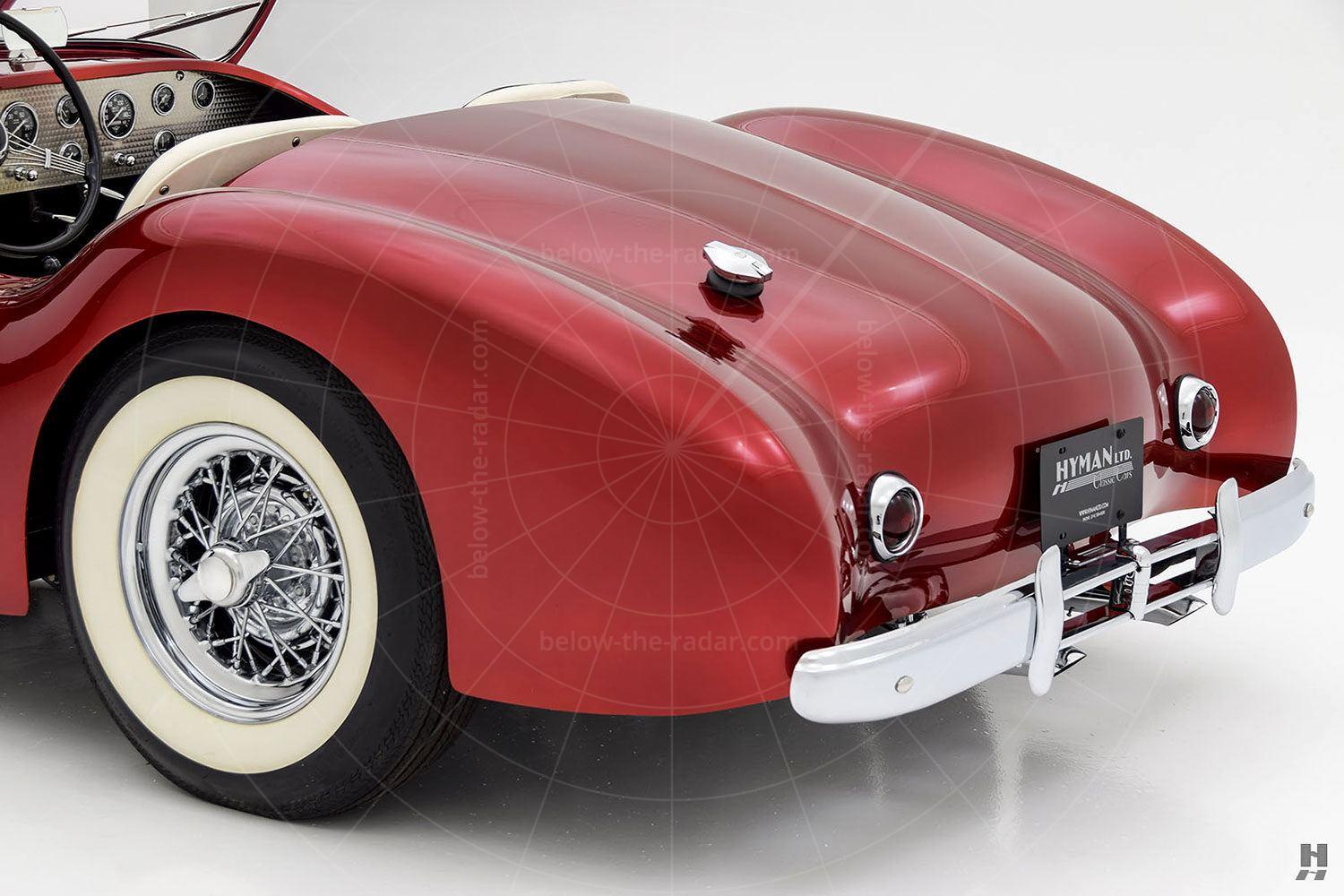

Unlike later mass-produced glassfibre cars, the G2’s body was hand laid, so it was remarkably strong and durable considering its light weight. Of the G2s that have survived (which is about a third of production), many are claimed to be in as good a condition now as they were when they were first produced, such is the build quality thanks to the glassfibre being about 1/8" thick.

The G2's looks were striking but what really impressed – apart from the quality – was the impressive dynamics. The low kerb weight that resulted from a glassfibre bodyshell was immediately clear; the G2 was faster and nimbler than anybody might have expected. Even better, because the engine was set well back in the chassis, there was a claimed perfect 50:50 weight distribution front to rear.

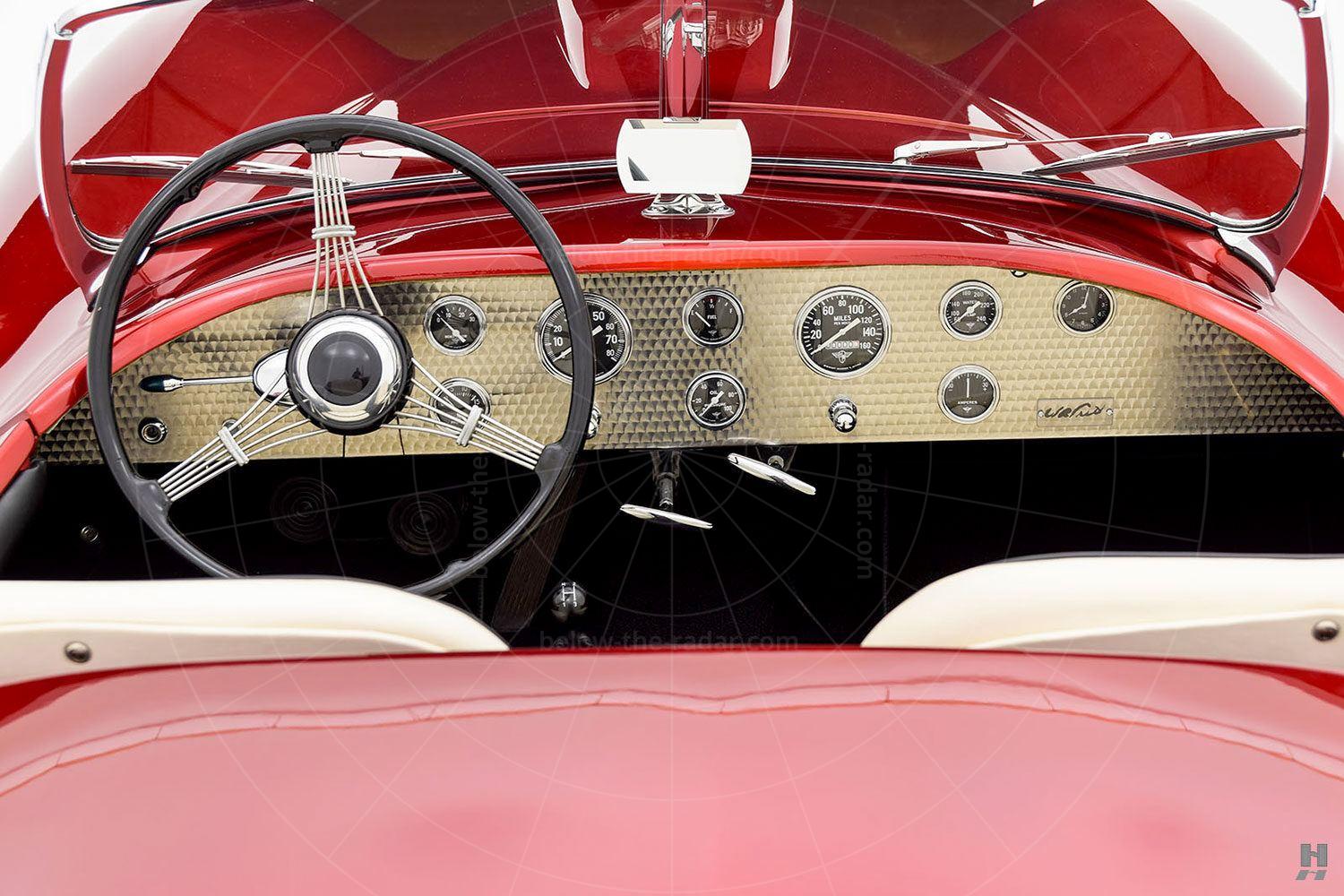

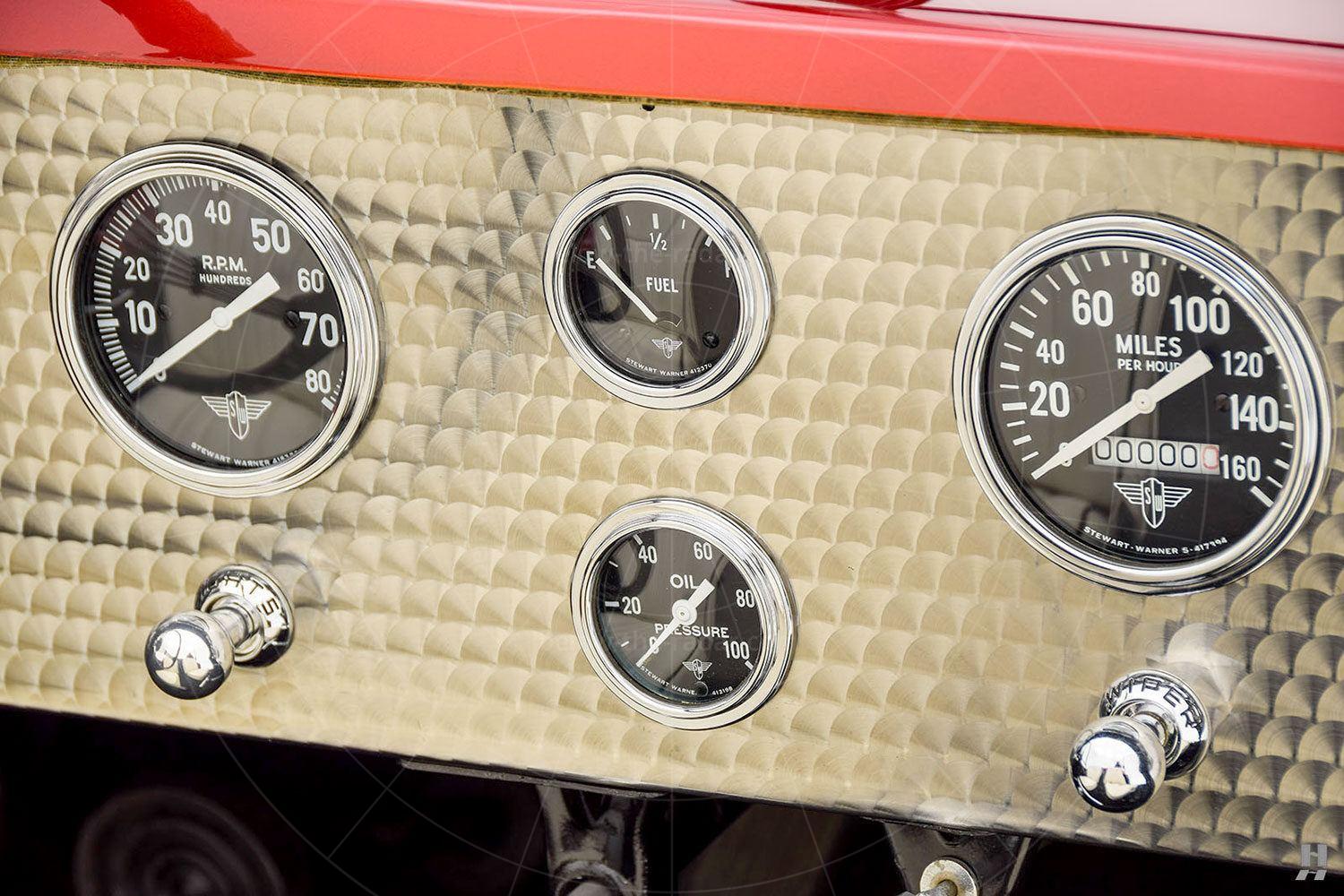

The G2's wheelbase was set at 101 inches and pretty much any engine could be fitted, according to the buyer's preferences. Complete cars were priced at $2950, or for the more impecunious there was a kit option, with the bodyshell priced at $650. A chassis could be supplied separately for $200 with a raft of other parts also available, such as a moulded dashboard for $18 and a second door for $75; as standard only a passenger door was fitted, so the driver had to clamber over the side. Other options included a glassfibre hard top and bucket seats.

Following hot on the heels of the G2, Glasspar supplied complete bodies for the Volvo P1900, the Kaiser-Darrin 161, and the Willys-based Woodill Wildfire. All of those offshoots are covered separately but it's worth adding a footnote here to another G2-based car that might have been, but remained a one-off.

In 1952, 41-year old actor Billy Vaughan decided to launch a new career by going into car manufacturing and sales. Based in New York, Vaughan commissioned Bill Tritt to rebody a Singer SM1500 with a G2 body; something that required significant work as the former featured a 91" wheelbase but the latter was designed for a 101" chassis. Tritt built the one car commissioned, which was shown at the inaugural International Motor Sports Show in Grand Central Palace. Despite being a non-runner, Vaughan claimed that the car had been driven 3000 miles to get there, and in a bid to garner interest he had some leaflets printed which pitched his new sportster at $2995. Nothing further is known about Vaughan or his rebodied SM1500, apart from the fact that it remained a one-off.

Despite relatively low production numbers, the Glasspar G2’s greatest success was that it spawned the kit car industry, which exploded later in the decade as a distinctly American combination of hot rodding and sports cars. That's not quite the end of the story though, as Tritt decided in 1954 to move on to an all-new car on a fresh chassis. Called the Ascot, it's dealt with in a separate article.

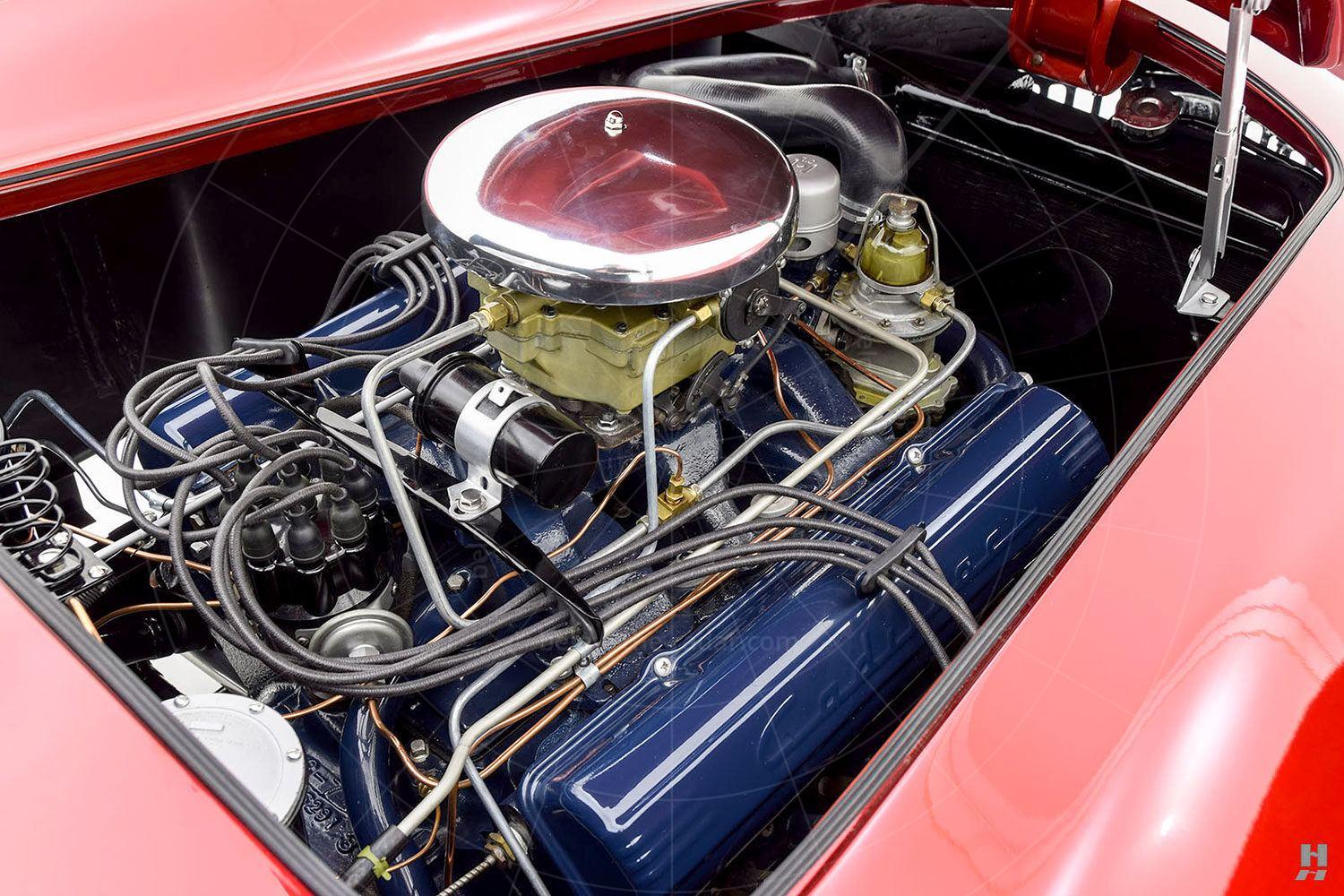

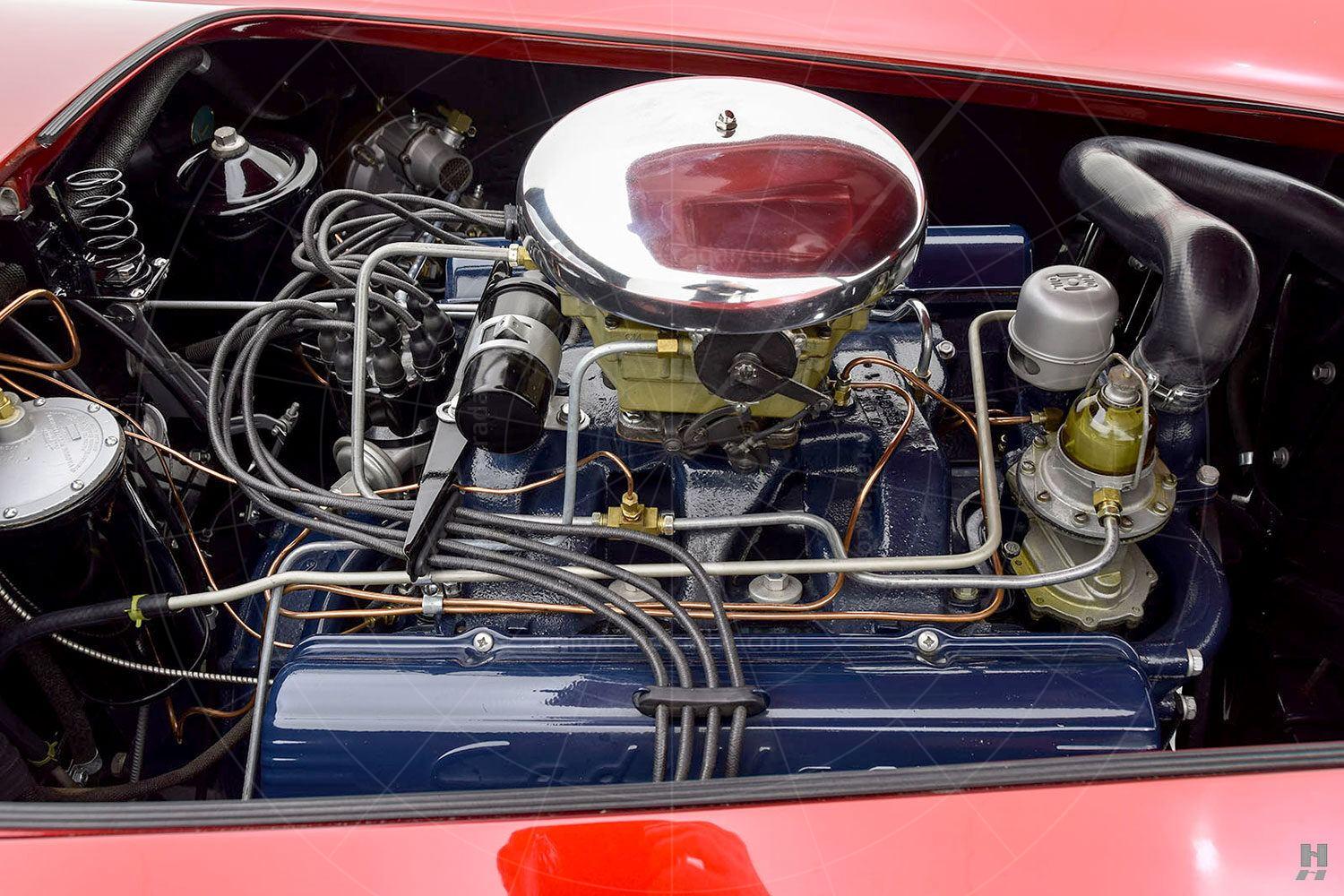

* The car pictured here is one of the last Glasspar G2s built. Dating from 1953 and according to Hyman Ltd which sold it, only 29 Glasspar G2s are known to exist from around 100 made. This one (chassis #G253038) is one of just 10 built by Glasspar in its Santa Ana, California workshop and sold as a complete, assembled car; the others were sold as kits. This car is also the only factory-built G2 to be fitted with Cadillac's overhead-valve V8.

Many thanks to Hyman Ltd for the use of its pictures to illustrate this article.